Plastic pallet is a logistics unit used with forklift, shelves and other logistics equipment. It can be used for storage, loading, transportation and handling of cargos. It is one of the essential logistics equipment in modern logistics warehousing. However, there are corresponding standards and requirements in pallet transport. Today, we will explain to you the standards and requirements for the transshipment of plastic pallets.

1. Selection of transport vehicles

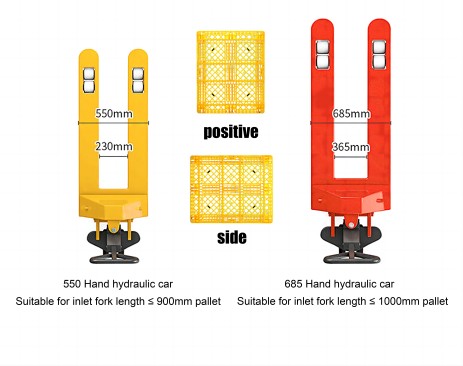

The transportation of plastic pallets cannot be separated from the assistance of forklift trucks. First of all, we will explain to you the standards required by forklift trucks transporting plastic pallets: in the process of using the pallet, the distance between the forks should be as wide as possible to the outer edge of the inlet fork of the pallet, and the inlet fork depth should be greater than 2/3 of the depth of the whole pallet. The second is the transport vehicle in the process of pallet transport standards and requirements: common trucks for 6.8 meters, 9.6meters, 13.5 meters, 17.5 meters. From the truck varieties can be divided into small trucks, high column trucks, high site trucks. In terms of the number of carrying capacity, high-ground trucks are the most suitable for delivery.

2. Precautions in pallet loading

Loading is usually carried out by mechanical forklift truck. In the process of pallet movement of forklift truck, the advance and retreat and the up and down should be maintained at a uniform speed to avoid the damage of the pallet and the collapse of the goods caused by the sudden brake and sharp turn.

3. Precautions in the process of car sealing

The driver who delivers the plastic pallet for the first time does not know how to seal the car. If the usual sealing method is still followed, it will certainly lead to the damage of the plastic pallet. How to reduce the damage caused by the sealing of the plastic pallet in the transportation process? Firstly, sponge is filled around the pallet to reduce the collision between the pallet and the truck. Secondly, splint is used to fix the pallet to prevent the shift of the pallet in the process of sudden brake and sudden turn. Finally, wrap the pallet with plastic film to avoid the damage caused by falling in the process of sudden brake and sudden turn.

Do the above points can greatly reduce the damage caused by the pallet in the process of transportation, so as to give full play to the use of the pallet effect.

If you have any other questions, please send them to our email address.

Post time: Nov-25-2022