Production, additional models and specifications of injection moulded pallets using the injection moulding process. A common facial structure is a grid, a plate. The base structure has Six-runners plastic pallet, Three-runners plastic pallet, Nine-feet plastic pallet, and Double faced plastic pallet. The specific production process is as follows:

1.Mold injection molding

A mixer will mix the matched ingredients to a certain degree before feeding them into an injection molding machine. After plasticization at elevated temperatures, the plastic pallet can be injected into the molding.

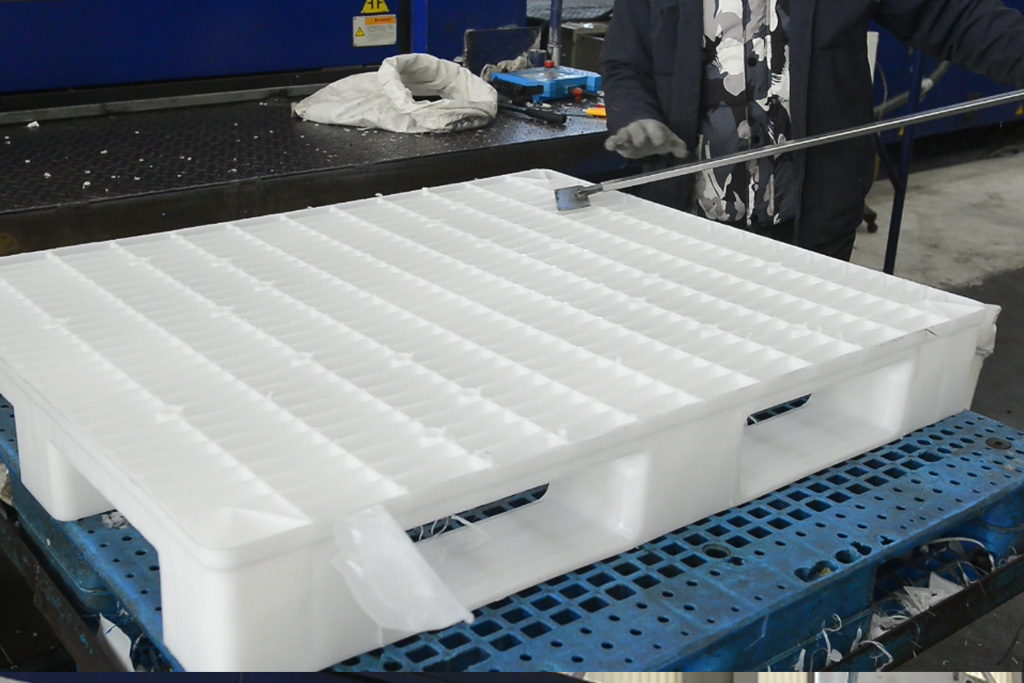

2.Cool and open the mould

The formed plastic pallet also needs to be cooled before it can be opened and taken out to the operating table by a manipulator.

3.Trim and beautify

After the plastic pallet is removed to the operating table, the edges are manually trimmed, the burrs are removed, and the anti-slip pads are installed. Finally, check the appearance of the pallet.

4.Sampling detection

We will irregularly draw a certain proportion of pallets from different batches of products for load-bearing, drop and other performance tests.

If you are interested in our products, feel free to contact us.

Post time: Dec-09-2022